Everyone in the garment industry from the CEOs to the middle management level have smartphones or any other mobile devices which have access to internet and most importantly YouTube. Interestingly, India has 31 million YouTube users and according to a survey by Google, almost one-third of these e-viewers access videos on their mobiles and spend over 48 hours a month on the website. Further, 70% of the emerging consumer class are tech-savvy who watch nearly 30% of YouTube videos on their mobile, spending one-quarter of the day on YouTube from their mobiles. That’s a lot of YouTube exposure! But how many actually use this resource for the growth of their business or careers, is debatable. In this article, StitchWorld discusses how YouTube can be used beyond watching movie trailers or funny videos, for managing various aspects of apparel manufacturing.

Analyse the Best Way to do Operations

IE executives at garment industry often struggle visualizing how certain operations are done after sample has been forwarded to them for production and even training the operators on methods of doing it. When looking for operations which usually take lot of time and might possibly become bottlenecks for assembly line production, say of shirts, they can simply search a solution by typing the phrase, “How to sew a shirt collar” where videos like “How to make a Dress: How to Stitch on dress collar” uploaded by Expert Village visually shows how stitching of two parts of collar is done after attaching of interlining, placing thread loops at corners to give angular shape or “How to attach placket on a shirt” which can be seen in a video “Attaching placket on a shirt-full video” uploaded by Michael Coates telling about check matching being done for attaching sleeve placket and even stitching if searching for “How to stitch sleeve placket” which has been shown in the video “Sewing a shirt sleeve placket” uploaded by Fashion Sewing Blog TV, which covers the complete cycle right from cutting of the component to stitching.

For products like 6 pocket cargo with higher SAM value, the flap pocket making method has been shown in “MiloMila.com Sewing Doll Cargo Pants-Side pockets”, uploaded by Wollyonline which can be searched by the phrase “How to stitch cargo pockets” which highlights the operation of first making the flap and marking its position followed by creasing and then stitching this 3D bottom pocket with folding and then sewing it. You can even watch videos on method of sewing variety of pockets like welt pockets as shown in the videos “How to sew welt pocket” uploaded by LastReelCinema where the front and back components of the welt pocket has been taken, folding the opening, have been ironed and then stitched over the outline of pocket mouth opening and then topstitch over the pocket mouth, folding the back component towards front and to match correct position stitching the folded back part all around or “How to sew side pocket” with similar explanation.

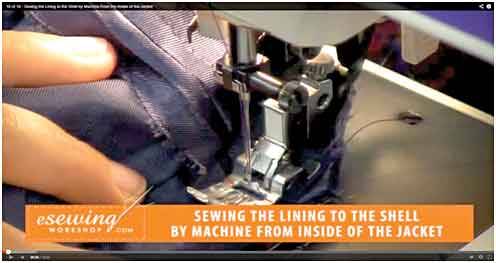

Even “How to attach lining in jackets” is available in different ways like in a singular video “jacket lining” by Jacqueline Johnson has suggested first joining front lining to facing and side panels to back and front, later joining the centre back together. There are 16 videos uploaded by eSewing Workshop on various operations of jacket including bottom and sleeve hemming, stitching shell fabric jacket and even for Sewing Lining to shell fabric shown in the video “16 of 16 – Sewing the Lining to the Shell by Machine From the Inside of the Jacket”, which shows the method of stitching lining to the jacket made with shell fabric with no stitches in view when seen from inside of a sleeve, from initially doing hand stitching at sleeve side and then stitching, keeping seaming of lining towards seam of shell fabric.

Selecting Machines

Time is money in the business of apparel manufacturing and a significant share of time is consumed in purchasing sewing machines or any other technology for manufacturing garments, reasons being the presence of numerous brands, types and technologies in the market, making it difficult for the companies to finalize a certain machine in the shortest time possible. Moreover apart from PDF & printed catalogues, the production managers of a company are left with no option than to ask a dealer or visit one for live demonstration of a machine. Now with the help of YouTube, production managers can zero down on a narrower set of machines for purchasing by showing the videos to supervisors, sewing operators, Industrial Engineers, buyers and anyone related. Later they can straight away go for live demonstrations. Also possible with the videos is to access the skill levels required for operating a machine, which further eases the process of machine selection.

Cutting Room Solutions

For spreading fabric, machines can be easily chosen according to the fabric being handled like in the video “Tubular Spreading Machine COSMOTEX” uploaded by Jordi Xarles which shows machine handling tubular knit fabrics with adjustable stretching system according to knit fabric. For automatic spreading Gerber, Morgan Tecnica, Lectra, Tukatech are some of the eminent players in the market. Latest one is from Gerber shown in the video “GERBER spreader XLs50 Automated Material Spreading Solution” from Gerber technologies which optimizes material utilization by accurate alignment of fabric edges eliminating end loss used for both woven and knits, while in the video “Topcut Bullmer Spreading Technology – Compact E1800” uploaded by the sewing machine group an advanced spreader with the ability to spread various possibilities and combinations of nap and face directions. Other solutions like Veith Pin IT have emerged which help in pin table check matching of shirts for spreading as shown in video “Checks matching of shirts with the Veith System Pin Table” by Veith Industries which focuses on fabric saving in woven checks and knits.

For cutting of fabrics, Computer Aided Manufacturing (CAM) has come into limelight since it makes work not only easier but also minimizes defects arising due to wrong placement of patterns for cutting or wrong marker planning reducing fabric utilization. Some of the firms who are making such kinds of automations in cutting are Eastman, Gerber, Lectra and Tukatech which provide complete solutions for different kinds of fabric. Eastman has produced Eastman Raptor as shown in the video “Eastman Raptor 75x – Multi-Ply Cutting System” uploaded by Eastman cuts which can automatically pull stacked material plies from the spreading table to a modular, bristle-block conveyor bed for reciprocating knife cutting of patterns. Another one is from Gerber “Gerber Technology Paragon Cutter – Metrics That Matter” in which after cutting the fabric, it generates reports into real time data including units and types of models of garments cut and cutter utilization which helps in improving productivity of cutter.

Other technologies which have been explored in field of cutting is the fast developing laser cutting promoted by Golden Laser as seen in the video “Business Suit Fabric Laser Cutting Machine Price” by Golden Laser Kelly where use of laser cutting machine has been shown to cut fabrics with precise finish. After cutting of pieces ticketing is done which is labelling of pieces with size and style and then the pieces are put in bundles to be carried forward in production. So, selection can be made on the basis of order quantity, fabric type and everyday consumption.

There are various machines being utilized in shirts and jackets for fusing collars, cuffs and plackets manufacturing shown in videos “Macpi fusing machine” uploaded by Macpi Group MACPI “flatbed fusing machine – Welco garment machinery Pvt. Ltd.” uploaded by Sonam Saini and “Maica Italia-MP2S – Adhesive Machine – Fusing Machine” by Maica Italia Movie which tell about variation in methods and effects produced by each machine depending on the requirement of the product. For ironing also, one of the advanced machines have been displayed in video “Cosmotex automatic ironing machine” and “COSMOTEX automatic ironing machine for knits” uploaded by Jordi Xarles in which the garments like T-shirts are ironed by long iron coil and rolled by conveyor belt towards a rack below. While in “the best shirts pressing machine” uploaded by the Beisler where model ADT-B138 2010 which does body, cuff and collar pressing in one machine.

Sewing Machines & Automates

Several videos are available on YouTube to see the working of not only sewing machines but also work aids and templates for operations like collar, cuffs and pocket stitching as shown in the video “Rich peace Automatic Template Sewing Machine – Operation Process” uploaded by RichpeaceKK and “Duerkopp Adler 806 Pocket Setter with flap attach” by Duerkopp Adler America. The functioning of buttonholing and button sewing various sewing premiers like that of Duerkopp Adler and GTN has been shown in the videos “Duerkopp Adler Class841, buttonhole indexer” and “Buttonhole and button sew indexer” uploaded by Charles Zimmerman, respectively. For trousers with average SAM as 35, various automatic waistband attaching machines, loop setting machines and for top stitching machines can actually help in providing better quality and accuracy in sewing. Their working has been shown in videos “AMF Reece FF-2500 – Sewing Unit for Top Stitching of Trouser Fly FRONTS” and “AMF Reece TW 5900 – Automatic Waistband Attachment Automates” uploaded by amfreece1. Some other specialized machines videos present on YouTube are automatic welt pocket sewing machines and cargo pocket sewing machines. One of the major advantages of YouTube is comparison of automated machines by going in the details of comparing the time required for the three processes of pick, sew and dispose, easily possible through the website.

Finishing Equipment

While traditionally finishing of garments was done manually, now different pressing machines are also there for garments, like shirts, trousers, and jeans. For trouser pressing, there are different machines available and their working systems is available in videos of MACPI 320, Pantastar 5351 which do entire pressing and folding of trousers. There are even about 15 reviews of different kinds of pressing machines used for pressing flap, sleeve seam, elbow hem pressing, back centre and side front pressing of shirts and jackets including jacket pressing machines like one of VEIT, BRI-13000/101and 905-101 for lapel pressing. There are also built-up systems videos which you can watch on YouTube like Shirt press VEIT 8900 and Pants press VEIT 8920 for doing complete shirt or pant as seen for shirt in video “VEIT shirt pressing concept” uploaded by veitmarketing, the system of pressing entire product by single system has been explained which does collar and cuff press and shirt body press. So, now anyone can know what kind of machines are required for different types of garments with even specialized effects.

For finishing the garment which is the last step before packing of the garment, the videos “Macpi 533 Series Steam Tunnels – Garment processing and reconditioning” uploaded by sewing machine group, “Leonard Automatic Steam Tunnel Finishers” uploaded by Lou Amico and “VEIT8657 Tunnel Finisher” uploaded by veitmarketing show how jackets and T-shirts are pressed going through a steam tunnel type cabinet which is closed by steam blowing inside for a while there’s form finisher video of “Ironing machine TUBIE-Trousers for women” uploaded by MyTUBIE1000 in which the form shaped like legs expands according to size of trousers blowing steam from inside.

Assessing Cycle Time of an Operation

Although video representation of operations is not a replacement for time study, an Industrial Engineer can quickly estimate the cycle time of any operation for calculating approximate production and so on. Analysis of sewing cycle times of machines ranging from sewing to finishing can be done using YouTube as well, which helps in giving clearer picture of speed of machines and time consumed in doing single operation. As the time encompassed is displayed live, the user can pause and analyse different sections or different cycles of videos to estimate time. Although maximum videos show very few cycles of the operation to record timings of multiple cycles and averaging out, in most of the cases those are sufficient for cycle study.

The sewing machine group Vibemac has uploaded few videos of back yoke stitching, waistband attaching and many others from which time study can be done. One of their videos “Vibemac 3650 EV8 operator China” shows entire cycle time of attaching loop to cargo shorts. Besides, this “AMF Reece S-311 Indexer-electronic eyelet buttonhole indexer” uploaded by amfreece1 has shown how the indexers make buttonholes in jeans and sewing cycle time is easy to calculate per jeans. Operations like sewing plackets of T-shirt which used to be a bottleneck operation has been simplified by an automat sewing variety of plackets as shown in the video “automatic placket machine” uploaded by sewing machine manufacturer Sahl International with sewing cycle, showed clearly from picking the front and back part of sample cloth, placing in machine, sewing and then disposing.

Conclusion

Along with benefits of watching work-related videos on YouTube, there are blush moments too! Like any other internet search, results sometime show totally irrelevant videos while typing keywords, like “brother snls” gives you Justin Bieber songs and Dear Brother (SNL dear sister parody) aired on SNL channel, SAM of shirt gives you recent launch of a song Sam’s shirt, trouser finishing gives “Trouser trumpet band” a comedian band attempting to do gigs in 9 different places in one night, ‘collar sewing’ key search gives you also “how to make easy quick release dog collar”, button holing throws up “Buttons kaluhiokalani – The future surfing”, a video on a sea surfer who had died recently. GSD gives you an answer which will make you roll with laughter which is German Shepherd Dog!

Leave a Reply