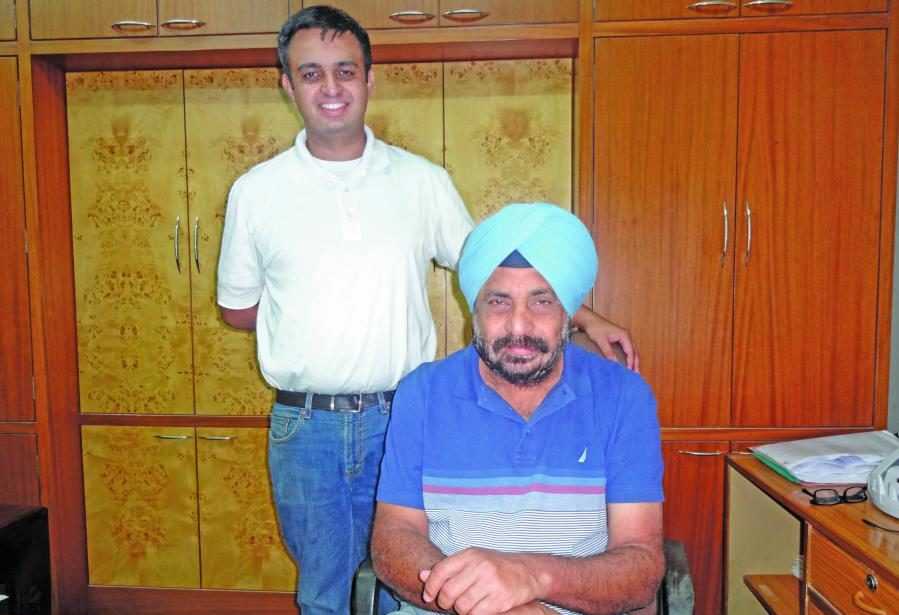

There are very few companies in Jaipur which are doing an annual turnover of Rs. 80 crore and having vertically integrated setup. And out of them very few will be expecting double turnover in next few years. But Suprint Textiles seems to be an exceptional company that has its own processing house with ZLD processing, having an equal stronghold on export as well as domestic market, and similarly competent in home and garment segment. Huge infrastructure, focus on product development, timely diversification and a set strategy are some of the main reasons that propel Suprint Textiles for growth, preparing it to double its business in the next two years. Apparel Online met Jasmeet Sodhi, Director of the company who joined this two-decade old company eight years ago and is instrumental in giving fresh direction to the company.

It was just a coincident that Jasmeet entered into business, without any strong base of textile, a year after his father Tejinder Sodhi, CMD of Suprint Textiles, initiated the processing house in an organized manner in 2006 at Bagru Industrial Area (Jaipur). “Our image has changed positively after having our own processing house, now we can easily approach anyone for business. It took a heavy investment of Rs. 40 crore and almost seven years to shift from Sanganer (Jaipur) but finally our complete processing and printing is under one roof, followed by ZLD with the capacity of 500 KLD. We are able to process 45,000 metres of fabric per day meeting all kinds of compliance norms. It allows us to supply at lower prices and in regular orders. We can meet any cost requirement on 45,000 metres,” says Jasmeet who strongly believes that in-house and organized systems are necessary to work flawlessly. In March this year, the company also shifted its printing to Bagru and invested in new machines also.

Using 85 per cent capacity of processing house for its own requirements, the company is targeting to add buyers that have at least 100 stores. “If you are good in service, big retailers will work with you for the long term. So we prefer this modal as we took the path of high turnover and low margin base regular business with continuous orders. At the end of the day, big infrastructure will give you high profit. After all, we are able to meet any price point just because of vertical setup and quick turnaround,” reasons Jasmeet. He shares that while the US market is bouncing back, Australia and Japan are almost constant markets for them, and it is the Southern American market, which is an emerging economy that has shown good growth for the company.Working with 15 to 20 overseas buyers in the home segment like Zara Home, Bouclair, Indiska, Pier1, Lucy B Linen, etc. in US, EU, Australia and Japan, the company’s export division in home business has a turnover of Rs. 30 crore annually and the preference is to work with big chain stores apart from one or two importers. The company offers anything related to cotton in home segment, like bedsheet, duvet, quilts, kitchen linen, cushion and curtain etc.; in garmenting it is known for women ethnic wear/kurties which is strength of Jaipur.

With all processes in-house, Suprint Textiles considers PD as a powerful weapon for its business and there are 50 odd people in the R&D team including eight designers. The company claims that regardless of any order, on an average the team develops 10 ideas/designs daily and two are converted out of them for final product. “We see PD as an investment not expenditure, as it is must to keep your company young, besides our job is value addition as we add value to the product. We have to upgrade our showroom every day, whether there is work in the market or not,” he adds. Along with exports, the company is equally strong in domestic market for its home products as every organized retailer to whom it is offering garments is also giving home business to Suprint Textiles, be it Pantaloons, Westside or famous home brands like Bombay Dyeing.

Four years ago the company added garmenting and today it has 450 stitching machines for garmenting and 150 for home segment. “We had excess capacity so we started garmenting and worked with organized retailers and from day 1 we saw good growth in this segment. Since, we already had a good sampling unit and R&D setup including all kinds of experts, so we just needed to add some machines and start garmenting. In the first year we learnt a lot and now we are enjoying it.

Western wear export is our next target though it will take some time because we have linked with such buyers who are already sourcing western wear from other places and we have developed our skills in the area so that they can be confident that taking western wear from us is as good as sourcing ethnic wear or home products from us,” shares Jasmeet.

Enthusiastic of further growth, Jasmeet expects to double the business in next two years with strong support from huge infrastructure, strong PD, quality manufacturing and set buyers. “Growth will come with advance setup, more trained manpower and better systems, and we have to upgrade ourself continuously. For us every day is a war and we have all things in place to fight it, so there is no reason not to expect good business, concludes Jasmeet.

Leave a Reply