Today, consumers want to be empowered by technology. They demand the ability to not simply purchase an item that they see for sale online, but desire first to select the style, colour, fabric and other characteristics and then see their planned purchase on a full 3D model as if they themselves are wearing it.

According to Forrester Research, clothing is the largest individual component of online retail sales accounting for nearly 40% in the US. In UK, web based shopping now accounts for 8.2% of all clothing sales and is expected to rise to 11.5% by 2013. Major investment in service and technology by several key players has driven market growth over the last few years.

Challenges

An online retailers’ major challenge is to improve the shopping experience and minimize the gap between buying online and in the physical retail site, where the customer can touch, feel and try on the garment before deciding to buy, resulting in poor online conversion rates, significant lost sales, reduced average order sizes and product returns of up to 40%. Another reason for online retail challenge is that while every person knows his generic size (S,M,L,Xl…), when purchasing online, that relative size is a subjective view and two shoppers with the same size of clothing, can have different body shapes, which can lead to different needs and results.

How does 3D simulation work?

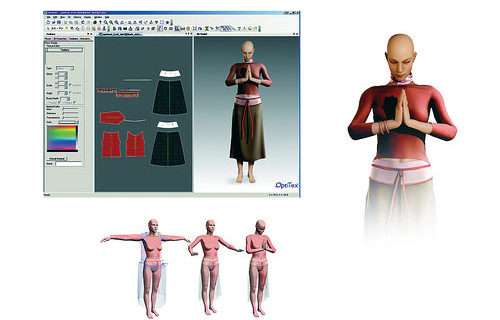

The simulation of fabric behaviour on a real body is based on an advanced simulation algorithm which uses a discrete set of finite elements that account for all internal and external forces that arise in reality such as stretch, shear, bending, gravity and the human body acting on the cloth. With OptiTex new technology any existing retail website can provide a full 3D shopping experience, using practically any web browser or web enabled device, including smart phones.

3D Simulation: Way Ahead

Customization and full 3D visualization capability is widely regarded as an essential requirement for the growth of web based apparel shopping. The possible benefits for retailers of online shopping are huge. The technology can help minimize inventory, produce for specific customer orders and avoid unnecessary sample production. Although making use of standard sizes enables manufacturers to produce at the lowest possible cost, each year they end up with tens of billions of dollars of excess inventory due to failure in selling the garments in those sizes and colours. Many leading retailers, including Nike, Tommy Hilfiger, Polo Ralph Lauren, Lands’ End and Target, have launched online clothing customization programs through which the customer provides data on personal sizing and software generates a pattern, forwards it to the factory, which in turn cuts and sews the material and ships the finished garment directly to the customer. Many analysts believe the trend will intensify.

Though the market for 3D software solutions for web-based apparel shopping is still at an early stage, Brides.com, Daz3D, Spoom, I Saw it First, Logical Apparel, Masskon, Muta Sport, and My Style Rules are using OptiTex to show their clothing collections in full 3D. Successful pilots, based on individual modules, can be accessed on the website of NikeTea. Many of OptiTex’s high profile large retail customers are today working with 3D Runway, offering the possibility of seamless extension for deployment on their online stores.

Leave a Reply