THE ONSET

As the famous Chinese proverb goes, ‘The journey of a thousand miles begins with a single step’. For Being Human, it meant a step in the right direction.

For a new Indian brand to touch a turnover of Rs. 250 crore in the first 5 years itself is a commendable feat, but the ride wasn’t always easy for this mid-to-premium brand. After facing rejections in the Indian market on the pretext of it being a celebrity-led brand, Being Human found its first lucky break with the Landmark Group which gave it 120 doors for the GCC – including UAE and Pakistan. This move, coupled with Mandhana’s foothold in exports, gave the brand an immediate boost. A wealth of contacts in the West earned the brand a distributor in Europe which instantly connected it with the markets of France and Spain.

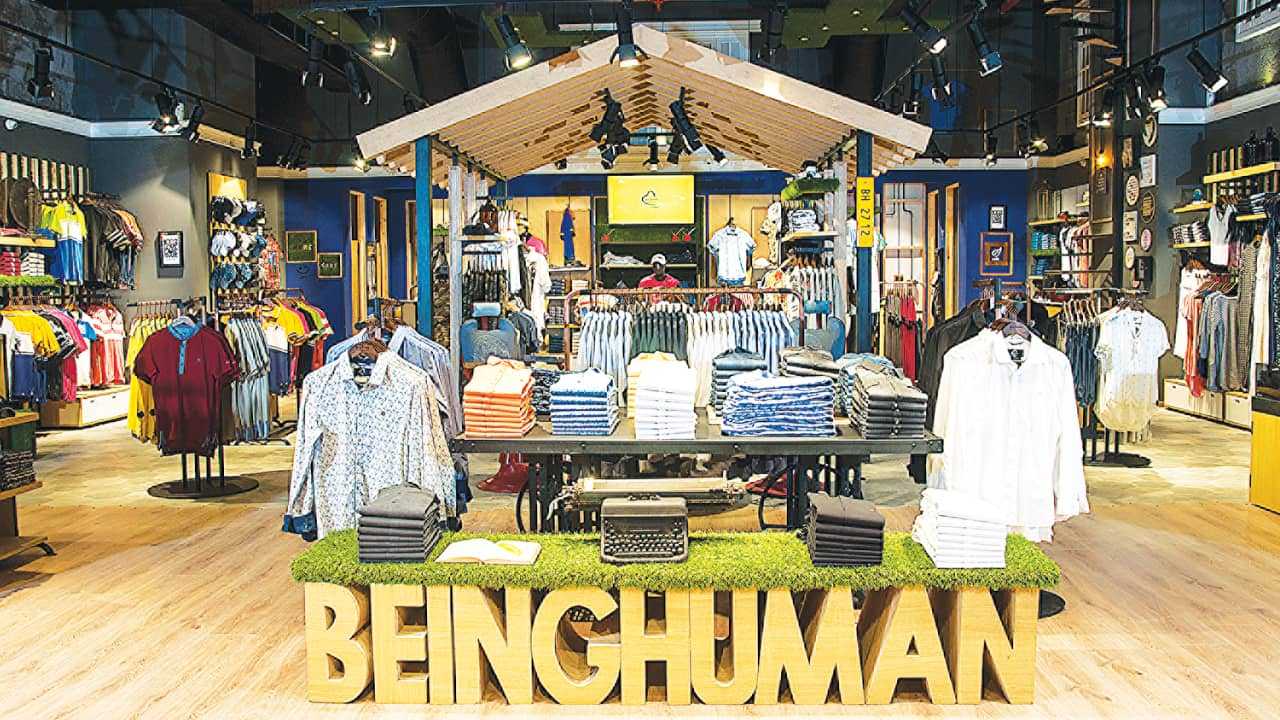

Domestically, the first year saw the opening of three stores – two in Mumbai and one in Chandigarh, which picked up post Being Human’s incredible performance in the international sector. It didn’t take long for the brand to prove its mettle owing to its international trends and quality standards, which straightaway positioned Being Human in the league of other international retailers such as US Polo, Levi’s, Jack and Jones, Benetton, etc.

Today, the brand boasts of 70 plus stores pan-India, with more than 500 points of sale among large format stores such as Shopper’s Stop, Lifestyle and Central. Internationally, the brand has expanded to Mauritius and Nepal, with a 10-door Canadian entry just underway.

In the online space, Being Human is a hot-seller at the likes of e-commerce giants such as Jabong and Myntra, the success of which led to the brand unveiling its own website in August 2018.

“We are one of the pioneers in India to have introduced a pure omnichannel experience – people have been talking about it since the past three years but we are the ones to have actually gone ahead and incorporated it into our business model.

“Today e-commerce has not evolved in India, everyone is looking for a deal, bargain but to come with a brand website and having such an experience, where you see so many orders are being paced, we know that customers are looking for brand experience and not just a bargain.” – Kunal Mehta

Bridging the gap between the physical and online store formats, the merchandise is shipped directly from the nearest store to the consumer within 3-4 days of ordering on the Being Human website,” told Kunal Mehta, VP Business Development & Marketing at Being Human to Apparel Resources .

MARKET SCENARIO

Built on the cornerstones of goodwill and hope, the brand’s USP lies in Charity, Celebrity and Fashion. Channelling the three into on-trend pieces, teamed up with a solid corporate social responsibility, makes Being Human a force to reckon with, for both buyers and consumers. This directly affects the rate at which the brand has been expanding.

“Metro cities account for more than 50 per cent of our expansion, though it has been increasingly observed that the growth in Tier-1 and Tier-2 markets has been tremendous. We are trying to leverage this interest and are putting our focus on these areas because we have seen that the total aspiration of our brand comes from the Tier-1 and Tier-2 markets,” Kunal said.

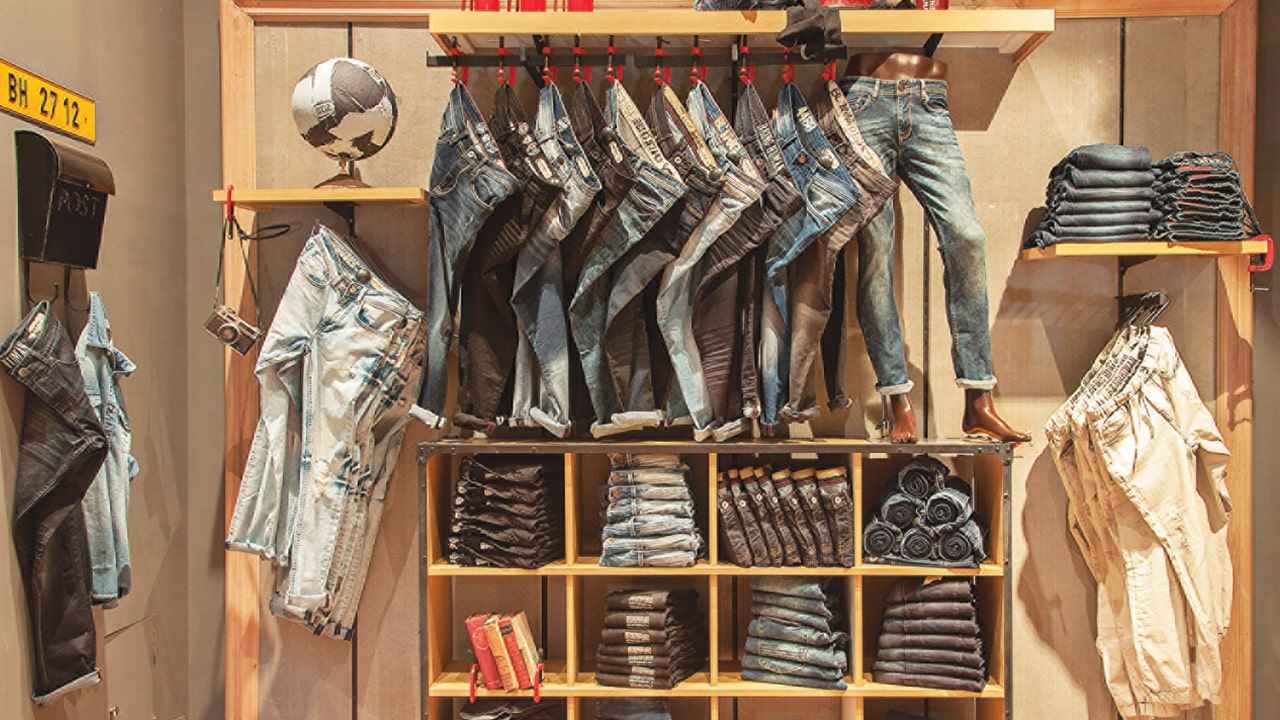

International brands enter metro cities first, creating a wealth of options and competition for domestic players, putting Tier-1, 2 and 3 markets on the top of the potential list for domestic players. The reign of fast fashion has affected each and every brand in the retail space, urging retailers to be on-trend, fast, varied and affordable. This has led Being Human to revise its entry-level pricing from Rs. 899 for a T-shirt coming down to Rs. 699, and Rs. 2,999 for denims coming down to Rs. 1,999.

“We haven’t compromised on quality but we have experimented with different kinds of fabrics and blends which we weren’t using earlier – even a Rs. 1,999 jeans or Rs. 699 tee will carry the same brand ethos. We’ve seen other brands moving towards the lower end of price point as well and it’s become the need of the hour to match competitive pricing,” stated Kunal.

“Working for both the export and domestic market, I have seen that the domestic market is a stronger and more difficult market as the demand for quality from the Indian consumer is really high. The Indian customer wants ‘value for money’. It doesn’t matter if a product is retailing at Rs. 799 or Rs. 699, he has to be satisfied. So quality has to be foremost, whether at a lower or higher price. Quality is the key factor that cannot be compromised at any price,” averred Purvi Joshi, VP International Business and Sourcing at Being Human .

PRODUCT MIX

Following the Spring/Summer and Autumn/Winter format, the brand releases two collections every year inclusive of 85 per cent menswear and 15 per cent womenswear. The brand works on 500 SKUs comprising the complete category, manufacturing 15-18 lakh pieces per season, or around 35 lakh per year.

The brand features a mix of clothing and accessories out of which, depending upon the season and its corresponding trends, 25 per cent of the mix is the core range, 50 per cent is raked up by mid fashion and 20-25 per cent is premium or experimental fashion.

“The entire world has moved towards value retail. Talking about India, with the advent of H&M, FBB, doing so well, people are getting great styles for a good, competitive price, and the category that we are in is ‘fast fashion’ basically. People don’t want anything to last more than 3-4 months, they want to change fast.” – Kunal Mehta

Owing to Mandhana’s strong roots, majority of the manufacturing that is around 85 per cent, is done in India itself (in-house in the brand’s factories based in Tarapur and Bangalore, and externally outsourced through vendors). About 15 per cent of Being Human’s total buying comes from China and Bangladesh, which they prefer for the import of their jackets and denim categories.

“Quality, pricing, delivery time – Bangladesh is known for these things. We get very good denims from Bangladesh, and it has been our prime vendor for the denim category. We are also importing winterwear and jackets from China,” Kunal said, adding, “In India, we prefer Tirupur in the South for knits, Ahmedabad for shirting, so our shirt vendors are based in Ahmedabad and Ludhiana. Both our in-house factories manufacture our denims and chinos, and our pants come from Bangalore.”

Describing the designing process to Apparel Online, Purvi said, “When our designers are about to start work, we give them a product matrix according to different categories along with price points and select quantities. If we consider price points at a higher stage, there is a risk of the collection going into complete loss. The entire matrix is broken down into price-points category wise, post which the designers start working on the tech files.”

She further elaborated on the sourcing process, explaining, “Tech files with different guidelines are given to our suppliers. The biggest policy of sourcing is: ‘Don’t put all eggs in one basket’; so we cannot depend on 1-2 vendors, if they fail, we are busted! Quantities are taken into account to plan suppliers along with suppliers’ review reports before placing future orders. All suppliers cannot be perfect all the time, so we review them after each order. If one performs well, we increase business with them, if not, then we reduce it after issuing a warning.”

According to Purvi, lead time varies from 90-120 days for all products, with a case-based fast track option that works on 60 days at max for certain styles. Replenishment timelines vary between 8 to 10 days with core styles being given the most priority, and in mid to high, only sizes that retail fast can be reordered. “We are a young brand; we focus on creating more variety in sales rather than replenishment to ensure that our customers don’t get too bored. The greater the options, the better,” Purvi explained.

During their Spring/Summer and Autumn/Winter buying, the product team always keeps a set percentage of the collection on standby. “If we see some style which is in trend right now, then we will keep that as a 5 per cent ratio buffer, so that we can get it immediately within 30 days lead time. So we keep that buffer and a 5-7 per cent of the standby stock which we can immediately put into production as and when required”.

BEST PERFORMING STYLES

Kunal attributes 40 per cent of the brand’s turnover to its T-shirts which are the fastest selling category. These are manufactured both in-house as well as outsourced.

To put it in his own words, “We’ve seen that for us, any campaign merchandise does very well – whatever we shoot or whatever Salman Khan is seen wearing, that does extremely well.” He then states, “Through markets, we have observed that South doesn’t pick up on trends as fast as the North and the West.”

This year, Being Human has opened its doors in upcoming cities like Siliguri, Jamshedpur and Bhubaneshwar. They are also targeting Shillong as a high fashion state which, because of its border connection to China, is deemed to be extremely fashion forward.

To test the marketability of the product in a new location, the brand initially starts off by opening one store in every city and thereafter upon seeing its potential, another store is added. Store size on an average is about 100-1400 sq. ft.

Leave a Reply